WE’RE HERE FOR YOU:

Product Sales & Service: 847.996.0739

MENUMENU

It signals a new era in portable, hand-held Ink-Jet coding, replacing antiquated hand coders such as stencil machines, stamps and roll coders, which are laborious and expensive in use and problematic with ink management.

Weighing in at just under two pounds – including its on-board rechargeable battery and ink cartridge – the HandJet®️ EBS-250 is the ultimate in lightweight, compact coding.

With its patented print technology, the unit improves and economizes ink management to make traditional manual coding methods like stencil marking, hand stamps and roll coders virtually obsolete.

By using solvent-based inks in an array of colors, the HandJet®️ EBS-250 provides fast, clean printing on a variety of corrugated materials, in addition to metal, glass and plastic substrates. The unit’s high-volume Ink-Jet cartridge efficiently provides up to 100,000 characters with a dot matrix of 7×5.

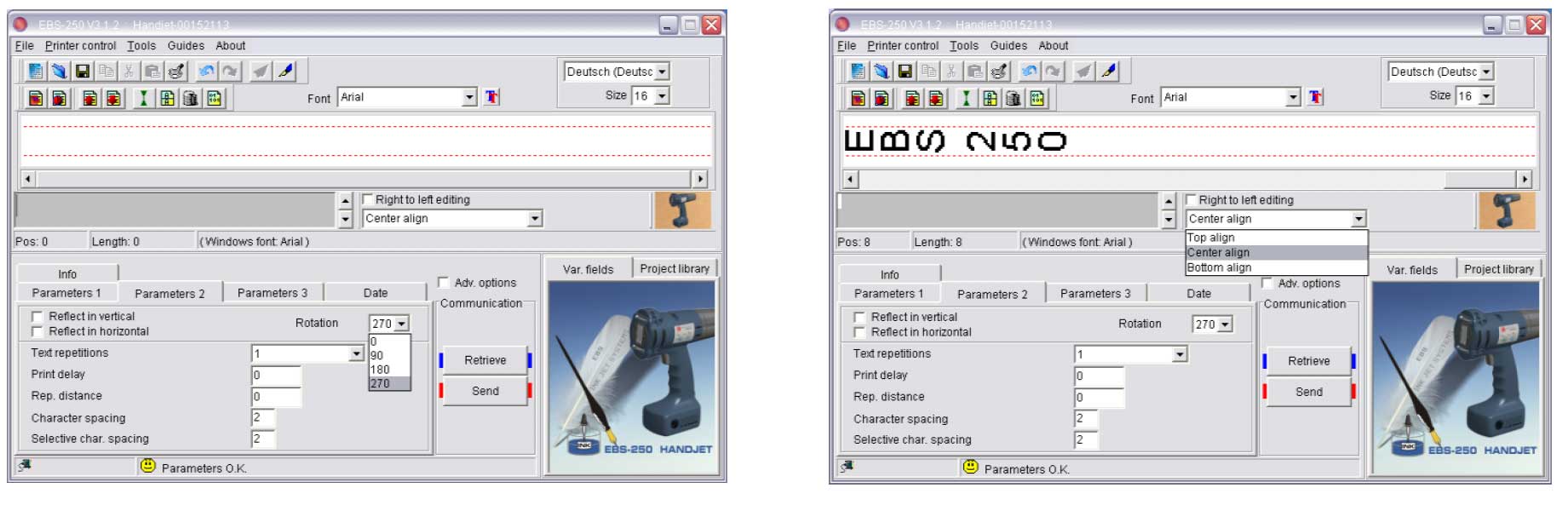

The HandJet®️ EBS-250 uses a simple MicrosoftTM Windows®-based program to format and transmit messages that are easily created on a personal computer. Messages can consist of alphanumerics and logos from Windows® fonts and symbols, as well as diacritical characters.

The hand-held system minimizes energy consumption to print for up to 50 continuous hours thanks to its rechargeable Li-ion battery – and recharging takes only two and a half hours

Nozzles: 16

Nozzle diameter: 150 μm

Minimum size of printed object: 1.38” (35mm)

Working position: Any angle

Printing: Enables printing of up to 10 texts in successive lines

Maximum characters per text: 1500 – includes control character for built-in fonts

Text and print parameters: 1 to 10 – loaded into unit via PC

Graphics: Editing and printing of graphical text and symbols using Windows® fonts (True Type) standard

Special characters: National (diacritical) characters and graphics

Variable fields: Date, time, ascending/descending sequential numbers, universal counter

Timing: Synchronized with rotational speed of the lower stabilizer, or at intervals by an internal generator

Power supply: Three (3) Li-ion rechargeable batteries

Operating time: Up to 50 hours continuous operation with fully-charged battery at 68°F (20°C); automatic low-battery indicator

Recharging: Automatically using external 24-volt, 1-amp DC power pack; charging time less than 2.5 hours

Ink: Cartridges; ethanol-, acetone-, water-based, or MEK, in various colors

Cartridge capacity: 3.7 ounces (110ml); prints approx. 100,000, 7×5 dot-matrix characters or 17,000 16×10 dot-matrix characters

Working pressure: 4.4 to 5.8 psi (0.3 to 0.4 bar) via internal pump

Operating temp: 33°F to 104°F (0.5°C to 40°C)

Storage temp: 34°F to 113°F (1°C to 45°C) – water-based ink; 14°F to 113°F (-10°C to 45°C) – ethanol- or acetone-based ink

Humidity: Up to 95% non-condensing; printer operates in rain on dry surface

Wireless Bluetooth® up to 300 feet

Text- and parameter-processing software; Windows® 98SE/ME/NT/2000/XP

Network up to 20 units from PC

Click images to enlarge.

Always turn the unit off before removing or installing cartridge

Be mindful of the cartridge expiration date

Turn on unit (press trigger and Print On/off Button at the same time

Wait for pressurization of the unit to stop

Move unit to product to be printed

Select message to print

Begin printing by

Pressing the Print On/off button

Pressing trigger once and releasing

Move EBS‐250 along product to be printed

Press trigger and “F” key until LED’s cycle and turn off

Loosen the ink cartridge

This releases the pressure from the ink system

Re‐attach the cartridge

This prevents dust, dirt or air from entering the back of the unit

Apply a moderate amount of cleaning solution to a piece of cleaning cloth, and gently wipe the nozzle plate

Store the unit in the case until next use

After 50 hours of use, or when the charge light is on, charging the unit battery is recommended

Please follow the EBS procedures, included in the user’s manual

This manual is included on the disk inside the carrying case

A new unit has been purged with the cleaning cartridge that matches the ink type

Install the ink cartridge and power‐up the unit

Press the Print On/Off button

Wait for pressurization to finish

Caution

Ensure adequate ventilation in the area

Point the unit downward into a hazmat‐type container or scrap cardboard

Press the trigger 3 times (within 1‐2 seconds) and hold the trigger in on the third press

The unit will emit 2 beeps, then the unit will ‘fire’ all 16 nozzles

This is called the PURGING procedure

When the purging starts, it will take approximately 5‐10 seconds until the cleaning fluid is replaced by ink

At this time, release the trigger

The unit should be purged of ink based on the following recommended intervals

Water Based Ink

Once per week

Ethanol Based Ink

Once per week

Acetone Based Ink

Once every two days

MEK Based Ink

Once every two days

Pigmented Ink

Every day after the shift is over

Purging the unit of ink

Power down (normal power down procedure)

Remove the ink cartridge

If the HandJet® cannot be switched off, remove the cartridge and cross the cartridge contacts in the rear plate with a wire (e.g. bended paper clip) until the HandJet® goes off.

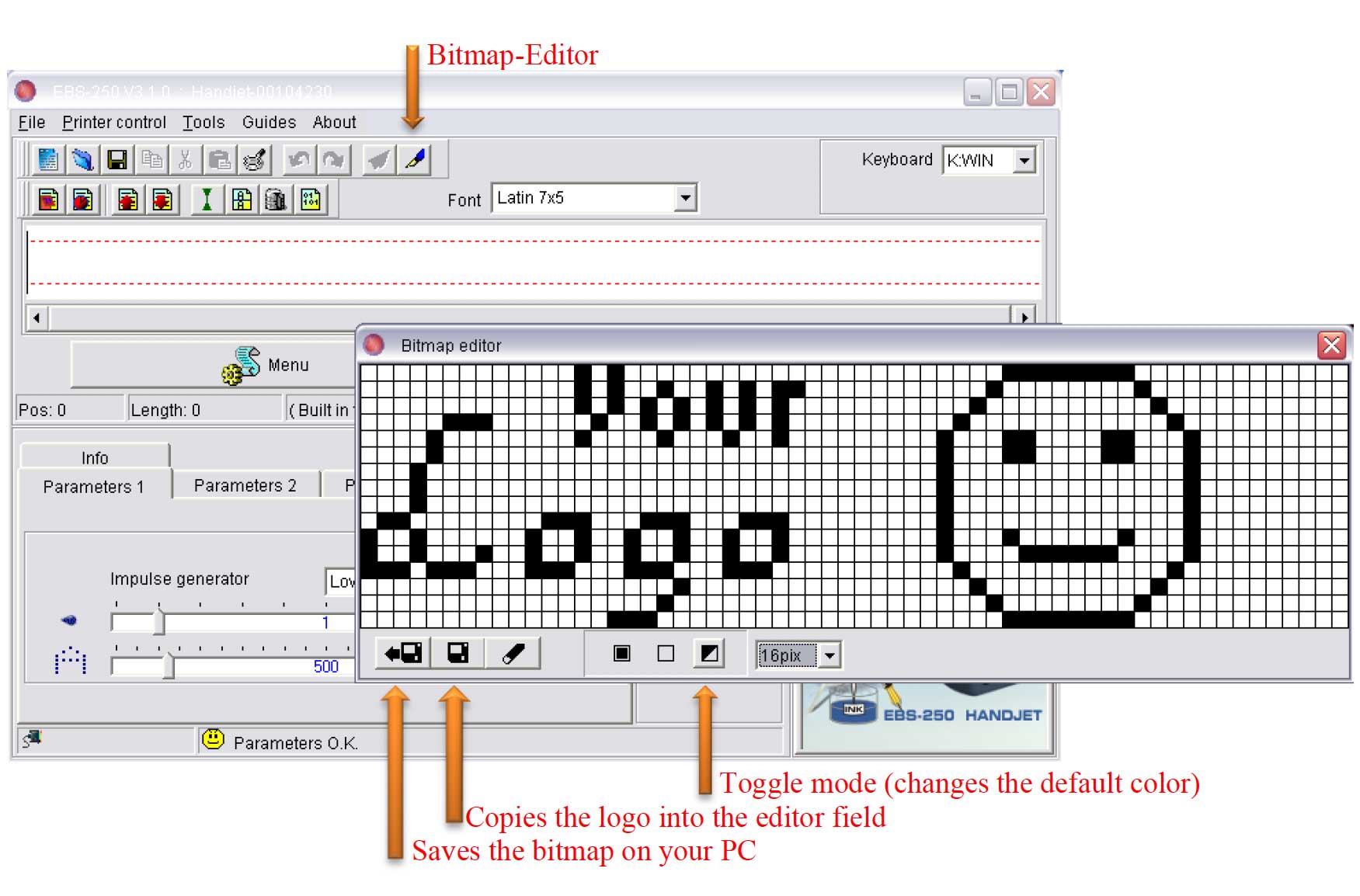

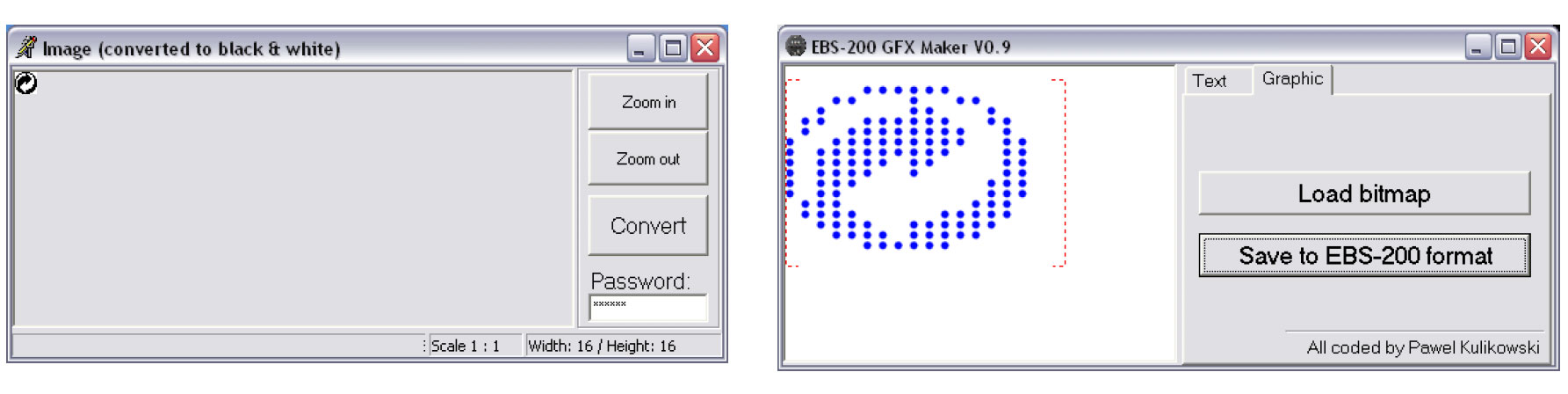

You can create an own graphic directly in the PC program.

For this open the bitmap editor.

An existing logo can be inserted as follows:

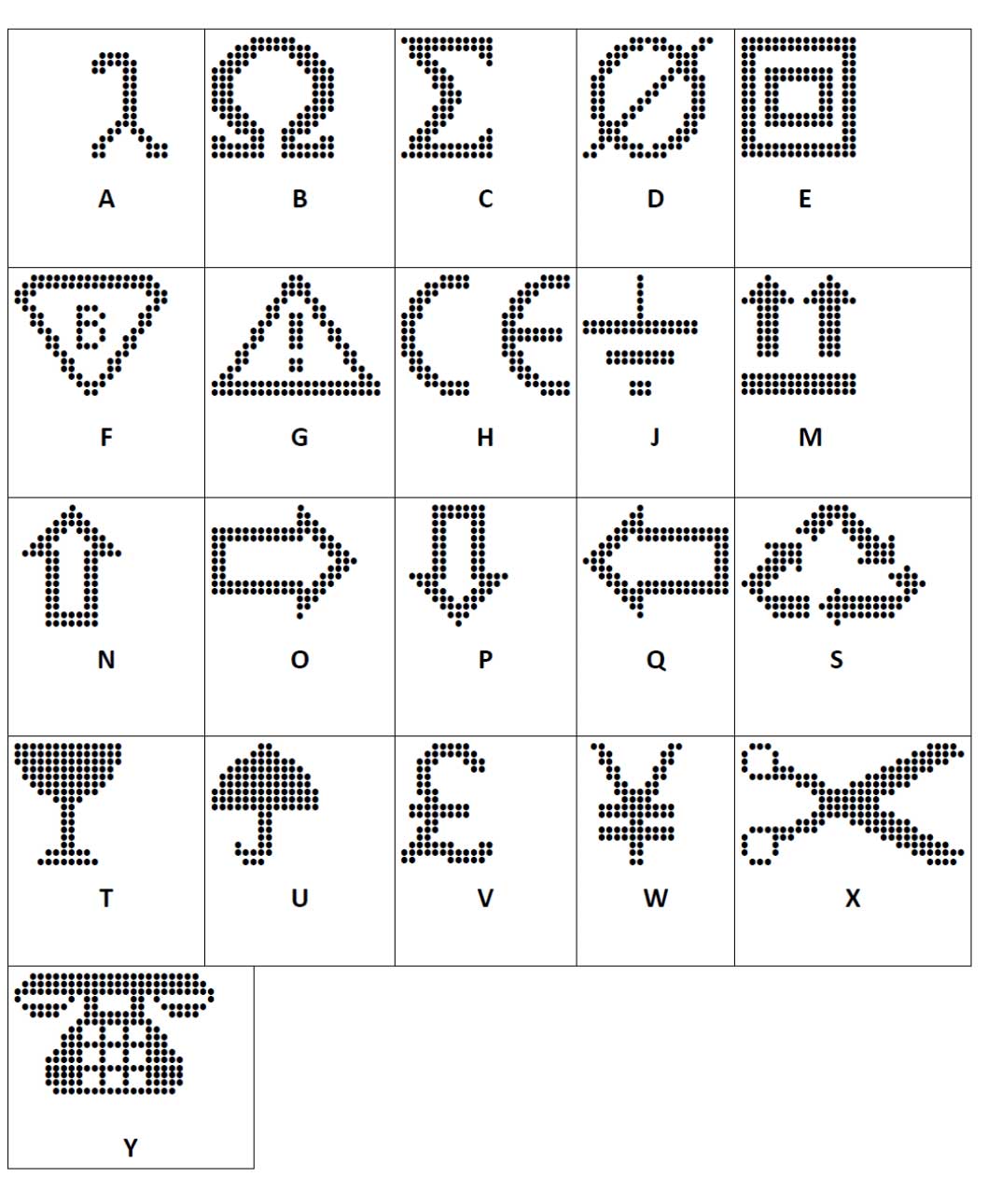

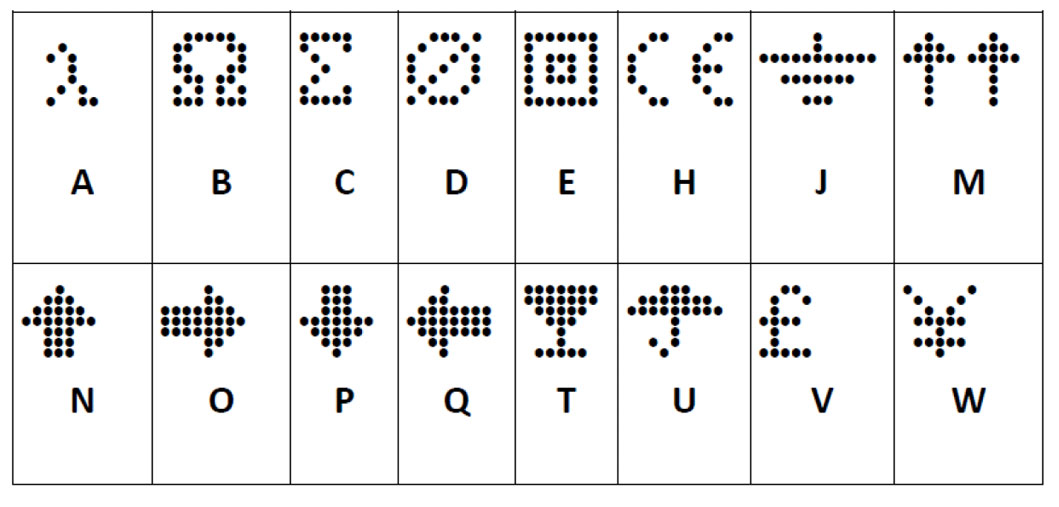

Select from the font list “Spec 7“ or “Spec 16“. The symbols appear after typing the corresponding capital.

Spec 7. Spec 16.

Spec 16.

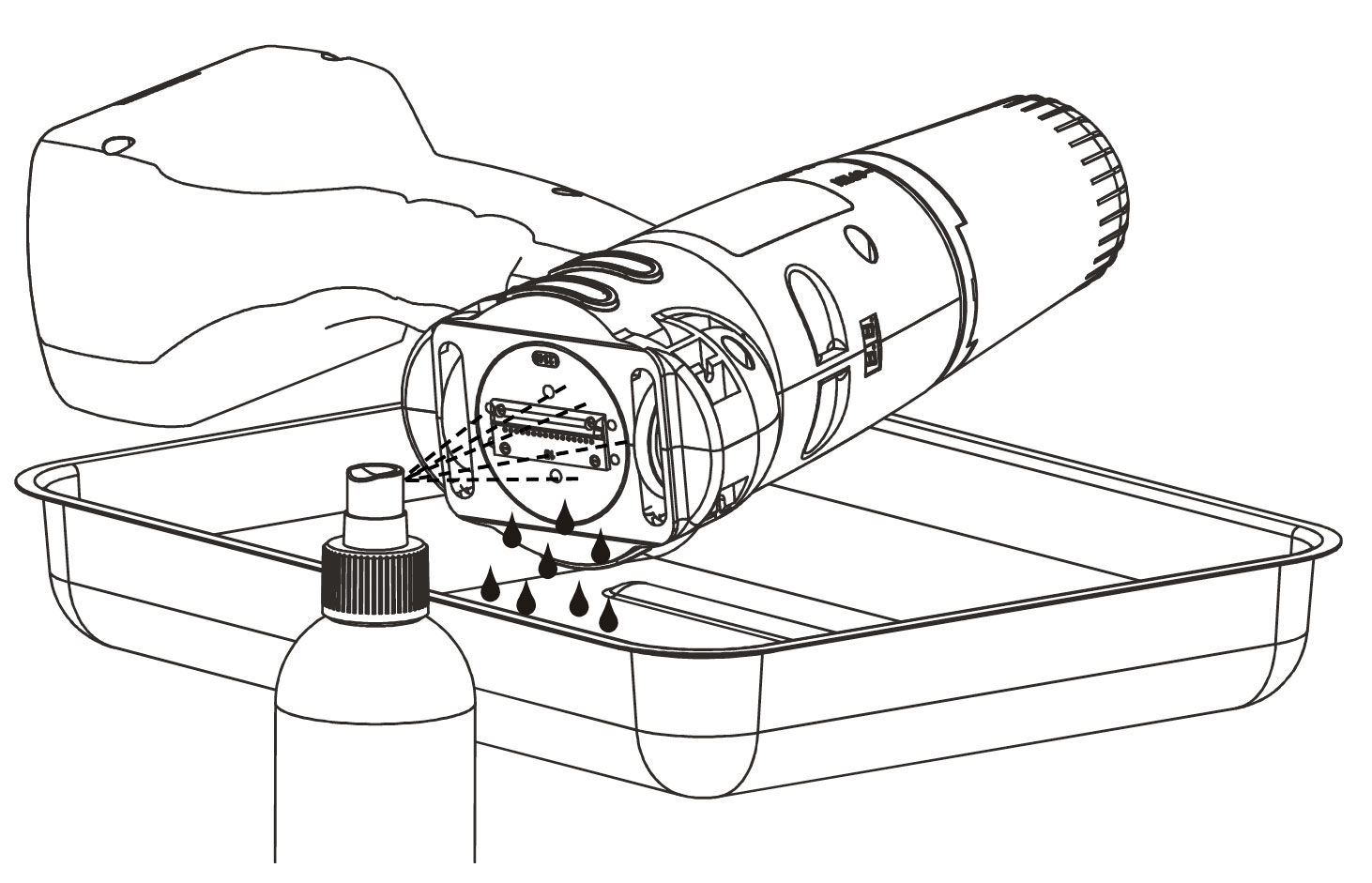

If the nozzle plate is dirty, clean it by spraying solvent on it. Hold the printer face down spray from below, that no solvent (mixed with ink) can flow into the unit or onto the guiding rolls.

When you use special inks, e.g. pigmented inks or fast drying inks, it can happen that due to pigments or ink rests nozzles will be blocked. In this case it is recommended to use a cleaner cartridge daily. Use the purge function to flush out old ink rests. This is also recommended when a HandJet® will not be used for longer time. You must take care to use a cleaner which is adequate to the ink base.

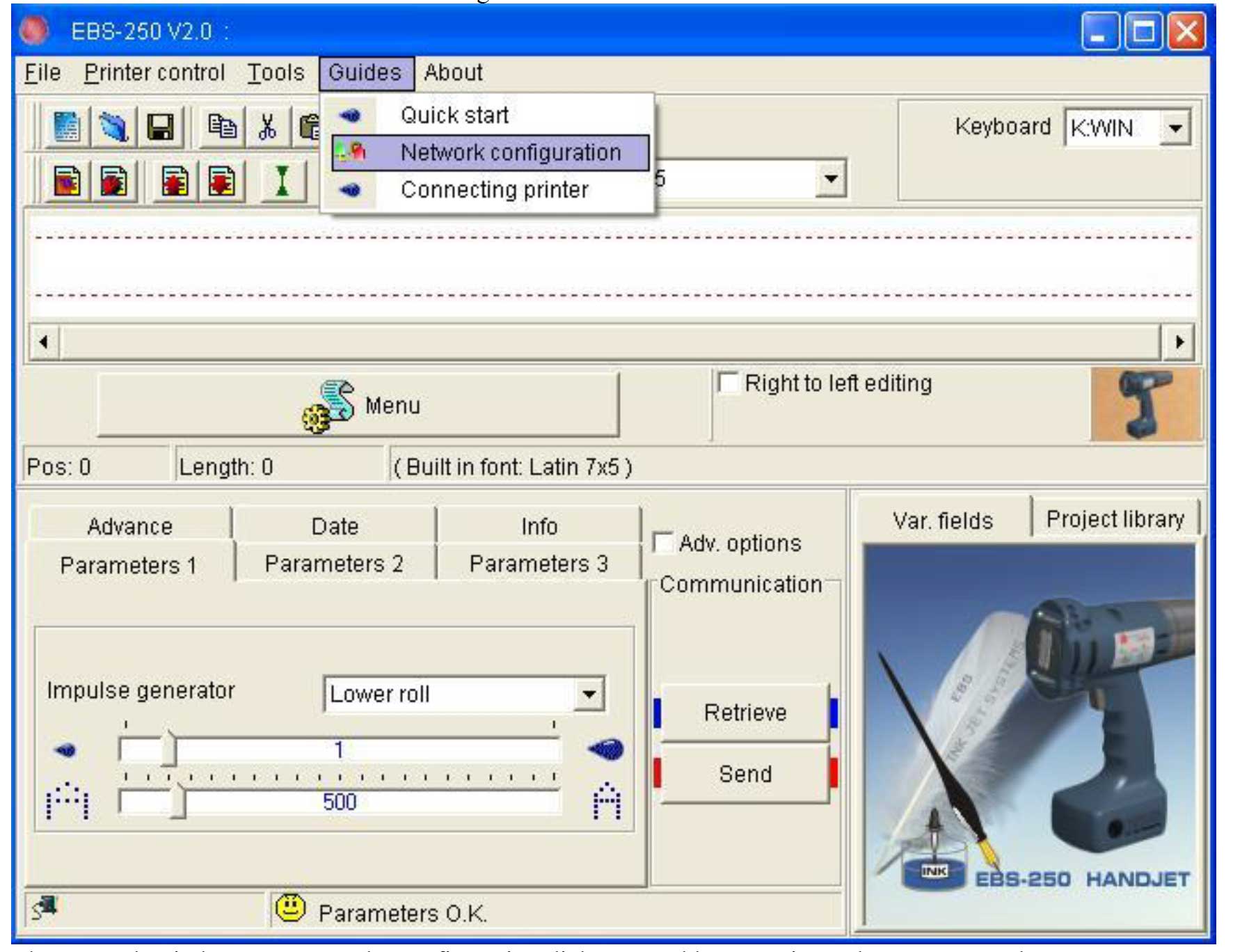

Click in the Guides menu on Network configuration.

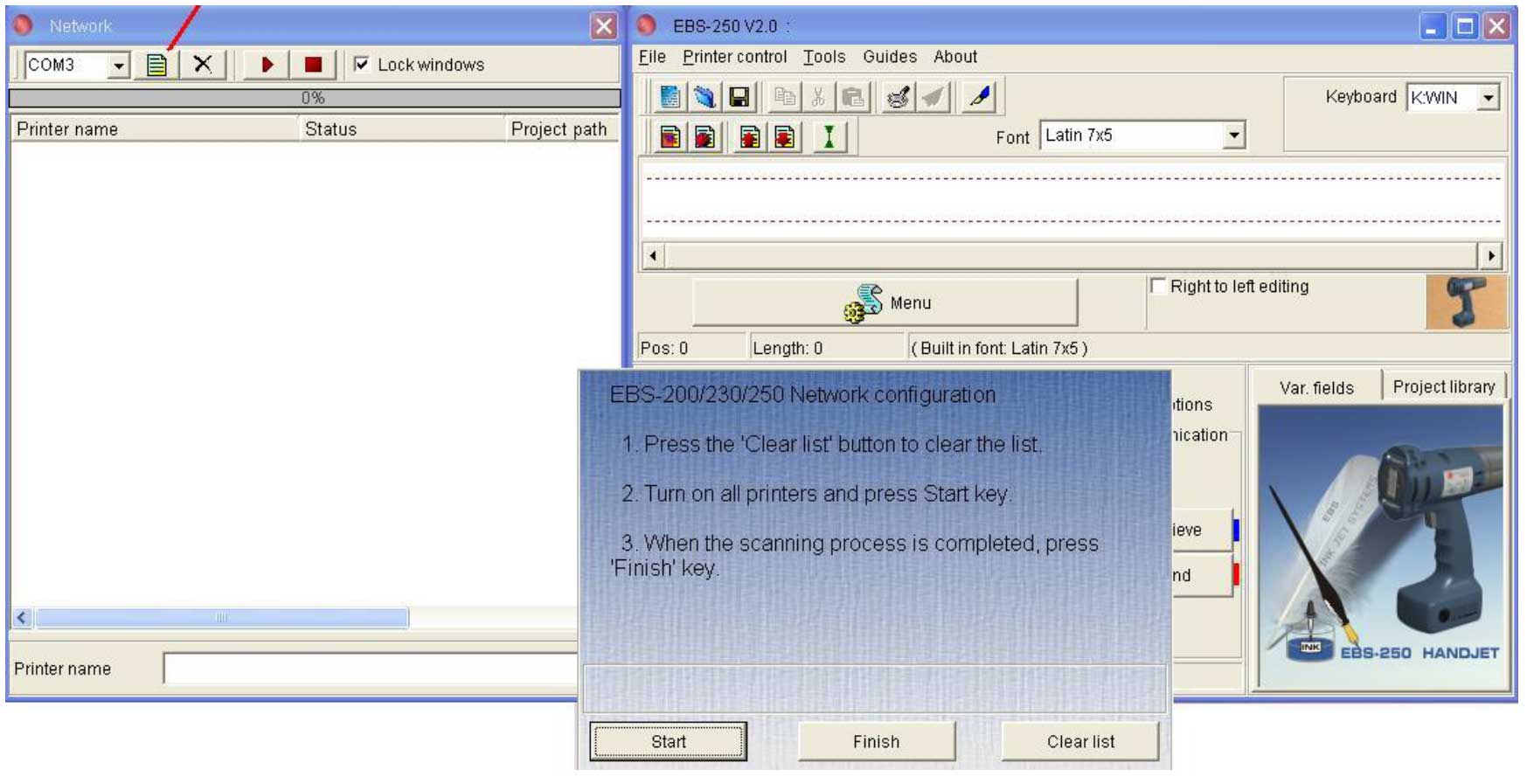

The network window appears and a configuration dialog. To add more printers later, you can also

click here.

All printers can be switched on at the same time. In the network window appears after each recognized and added printer an entry “Handjet® with its serial number. After finishing the network highlight this printer in the list with which you want to communicate.

All printers can be switched on at the same time. In the network window appears after each recognized and added printer an entry “Handjet® with its serial number. After finishing the network highlight this printer in the list with which you want to communicate.Yes! Regular maintenance on your EBS-250 printers is important to keep printers operating smoothly. Download cleaning instructions and find out how to clean the nozzle faceplate, the recommended time for periodic ink purging as well as review a step-by-step guide to purging ink out of a printer. Download the PDF.

Our warehouse is stocked with a large inventory of Ink‐Jet printers and supplies which means that you get your printers and supplies delivered when you need them.

To ensure proper setup

and operation of your Ink-Jet printing systems, we offer cutting-edge training sessions on all of our products either on site or at our facility.

EBS Ink-Jet Systems USA, Inc.

1840 Industrial Drive, Suite 200

Libertyville, IL 60048

Subscribe and receive our newsletter — Helping You Make Better Marks News — filled with the latest information on cutting‐edge solutions for contact‐free marking and coding, including new product developments, user tips, print sample requests, upcoming events, and more!

We respect your privacy and will not share your information. This newsletter is distributed every other month.